Another project that has long been overdue! This little window nook was one of the spots in our house that sold us when we bought it. When we did the home tour, I easily envisioned a little sitting and reading nook for the window. Well, over three years later, we FINALLY have our window seat nook! We obviously have a long to-do list seeing that it’s already been three years and we just got around to completing this project!

Actually, one of the main reasons that we waited so long to complete this project was because this window seat nook is where we had our puppy playpen and crates. This window seat is right off our entryway so it was easily accessible to get to when we came home to let the puppies out. But! Figgy and Frankie no longer need a playpen and if you’ve been here before, you know that I recently completed our entryway closet makeover – the new spot for the dog crates! Which left us with an empty space and the perfect opportunity to get started on the window seat project.

Check out what it looked like before we started! Just an empty space waiting for some love!

How to Build a Window Seat

This post may contain affiliate links where we earn a small commission on your purchases at no additional cost to you.

Our window seat is 89 1/4″ wide x 16 3/4″ tall x 24.25″ deep. The below supplies is what we needed for our window seat size, so you can use this as a general guide as to what wood pieces you’ll need. Basically, the entire structure is built with all 2x4s. We had some scrap 2x4s from other projects, so used what we had leftover and then bought some additional 2x4x8s. The rest of the supplies listed is all for the finishing look!

Also, we decided to add hidden storage underneath the seat. Who doesn’t love extra storage?! The supply list below includes what we used to create that as well. Since this bench seat is so long, we created two hidden storage doors. We plan to use these to store all our patio cushion seats in the wintertime since it’s not the most accessible to get to since we have the seat cushion above the doors.

WHAT WE USED FOR SUPPLIES

- 1 – 3/4 x 2 x 8′ Plywood Panel

- 1 – 1/8 x 4 x 8′ Sanded Plywood Panel (we actually like using this plywood paneling for projects. It’s a little thicker than 1/8″)

- 10 – 2 x 4 x 8′

- 1 – 1 x 3 x 8′

- 1 – 1x 6 x 8′ primed MDF board

- 1 – 1 x 3 x 8′ primed MDF board

- 1 – 1 x 4 x 8′ primed MDF board

- 2 1/2″ screws

- 2″ screws

- 2 – 1 1/2 x 30″ Piano hinges (for hidden storage)

- White Spray Paint (for hidden storage)

- Finishing nails

- Caulk

- Paint

THE TOOLS

- Miter Saw

- Circular Saw or Table Saw for ripping wood (I got this circular saw this past Christmas and it’s AMAZING)

- Jig Saw (we needed this for the air vent)

- Kreg Jig

- Brad Nailer

- 1 1/2″ Hole Saw drill bit (for hidden storage)

- Drill

- Level

- Measuring Tape

- Pencil

- Stud Finder

- Safety Glasses

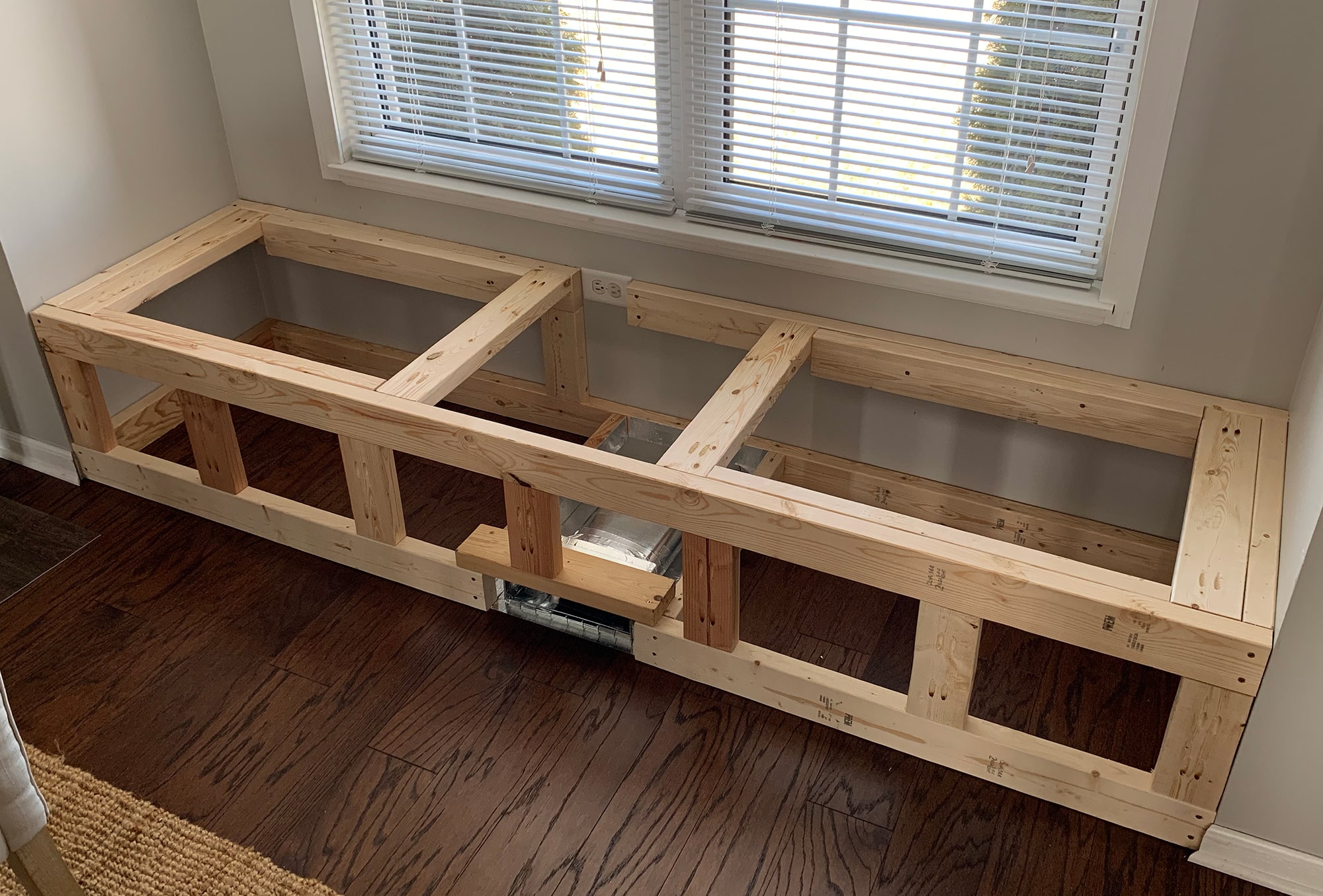

Building The Frame

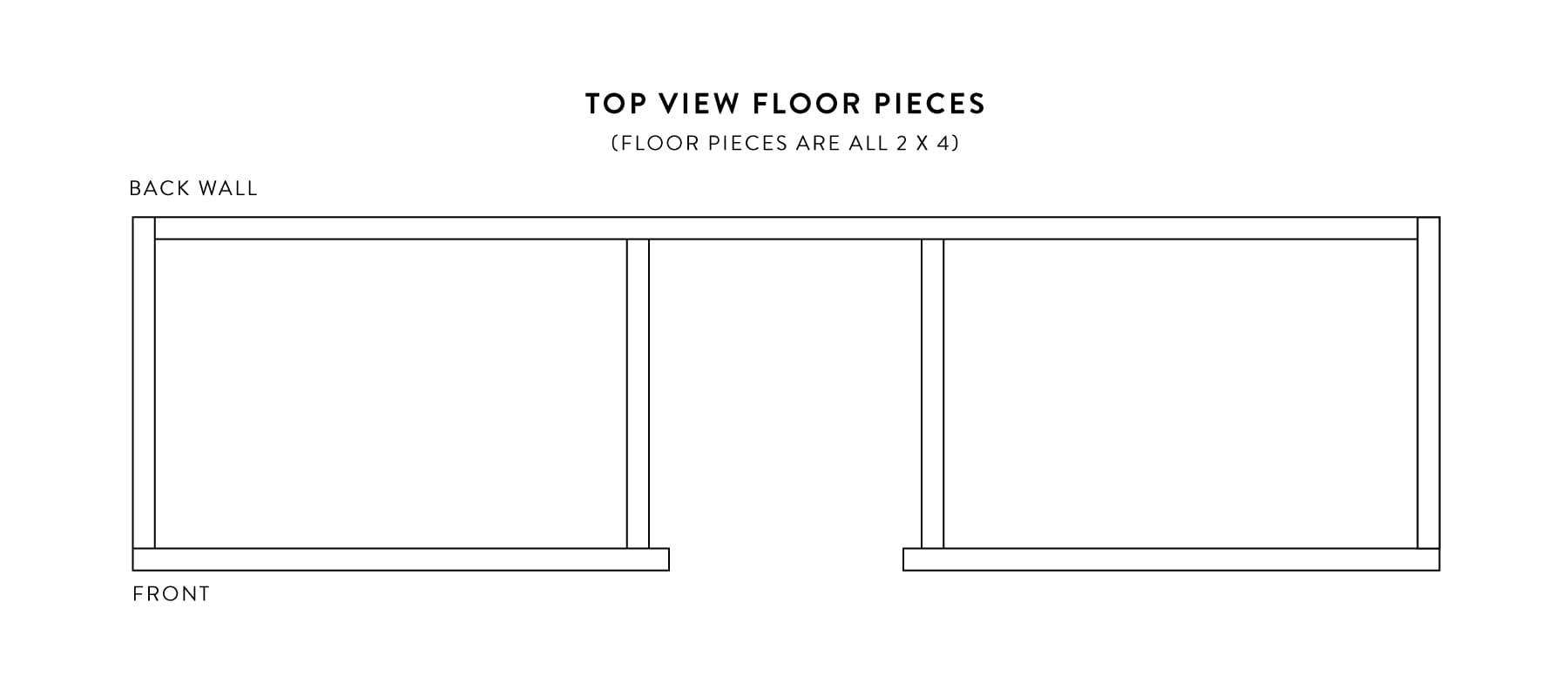

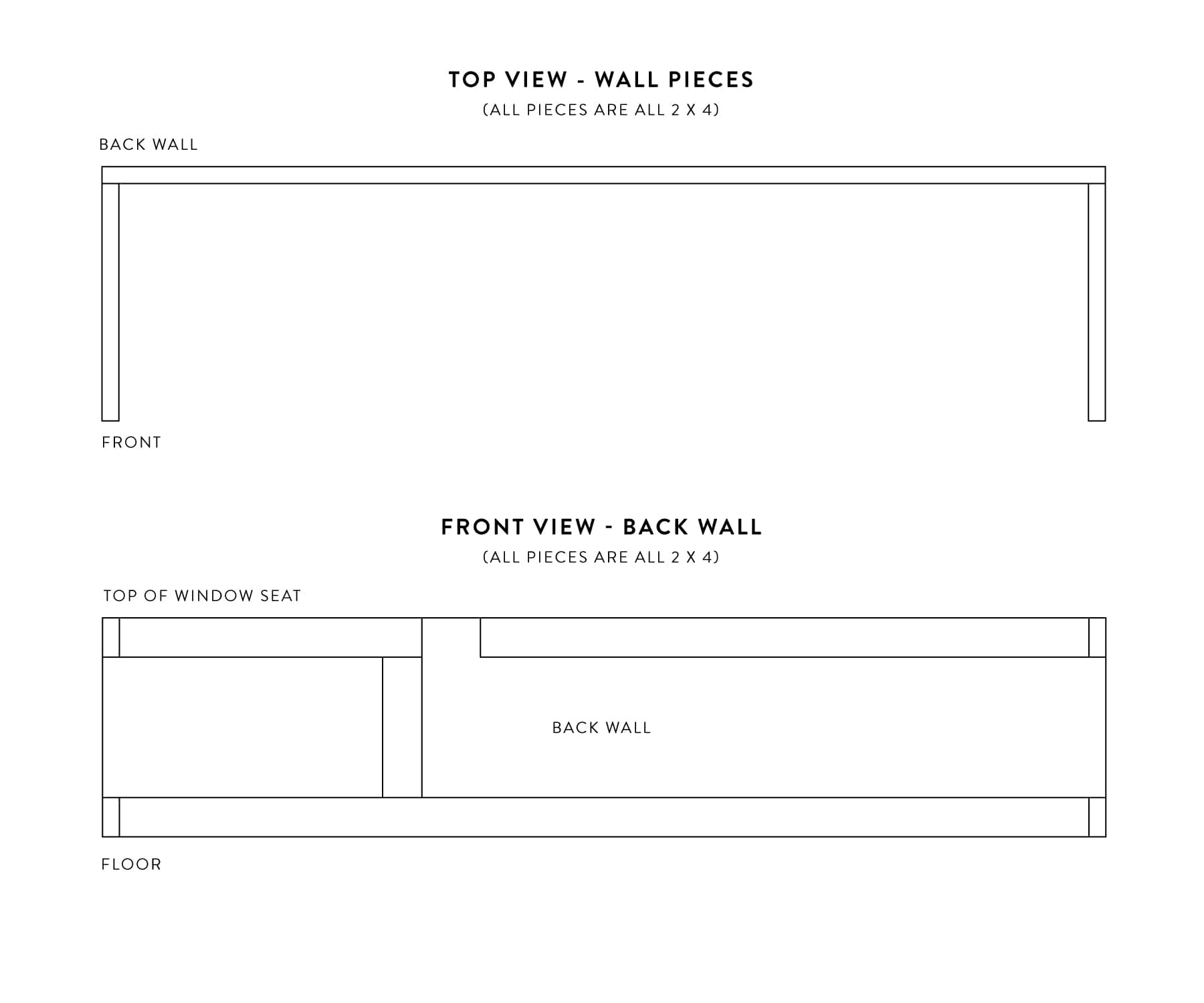

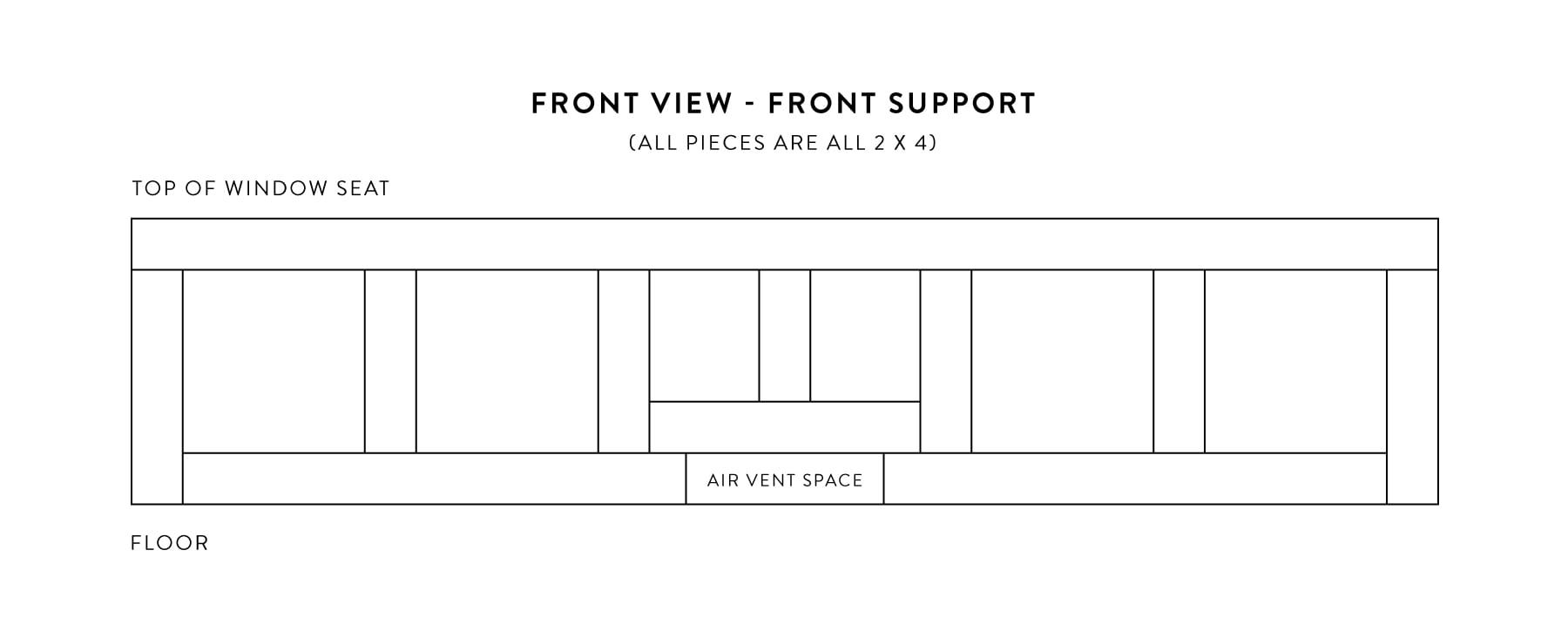

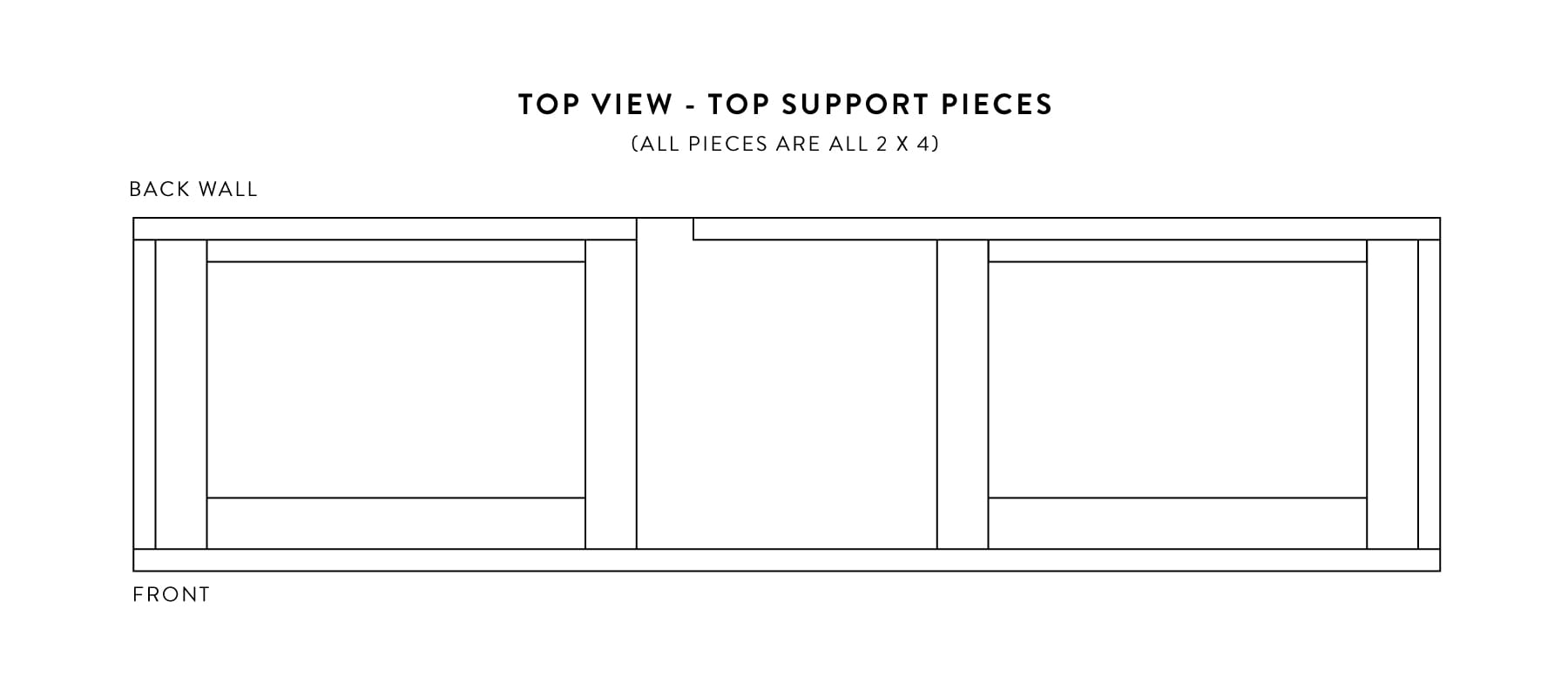

I am 110% a visual person. So before we start any project that requires extensive building, I like to draw up some “Structural” plans on how it should be built. We use this as our guide and what we refer to as we are building. It’s definitely helpful to have! I don’t have any fancy software that creates 3-D views, so all of these are just flat, 2-D views, but it works! I’ll share those with you along with the process photos we have, so you can reference between the two.

STEP 1 – Floor Pieces

First, we removed all the floor moldings since we will no longer need those. Then, we started building the window seat by building the floor frame first. When you attach the 2 x 4s to the wall, always make sure to screw into the studs for maximum support. We used 2 screws per stud.

As you can see, we have a floor air vent in the nook area. So, we had to extend the air duct out to the front of the window seat and decided to box in that section of the window seat. We also lined the floor with the aluminum foil tape to seal the entire air duct we added here.

Important tip

We built our structure to be flush with the front wall since we decided to add window trim around the window seat area. In doing so, the front finishing pieces we added to the window seat, will sit flush with the trim pieces. If you don’t plan to add trim around the nook and want your seat to sit flush inside the window nook area, make sure to adjust the depth of your seat to fit those front structure pieces inside the space.

STEP 2 – Add Wall Support Pieces

Once we had all the floor pieces cut and installed, we added the wall support pieces to the back and sidewalls of the window seat. Again, we used 2x4s pieces and made sure to screw into the studs!

Don’t forget to grab your level to make sure your boards are level on the wall! It also helps to measure and draw your lines on each end of the where the boards will be placed to ensure they’re level (unless you have un-level floors… ?).

As you can see in the above photo, and within our plans, we have an outlet on our back wall. So, we had to cut around that for the back wall support.

STEP 3 – Build Front Structure Supports for Window Seat

This is where you’ll need the Kreg Jig! To make things easier and to cut down on time, we pre-cut all our vertical supports for the front structure. Then, we made all the pocket holes in each vertical support. Once we had all the pocket holes created, we attached them to the top, front support board.

We attached them to the top board BEFORE we added it to the rest of the window seat structure. This way, it made it easier to attach all vertical supports to the bottom board, without having to squeeze in each vertical board between the top and bottom front supports.

After we attached all the vertical supports to the top cross support, we then took this entire piece and attached all the vertical supports to the bottom floor support.

We had the pocket holes face the front of the support to make it easier to drill the screws into each board. Plus, this will be covered with the 1/8″ plywood face, so they will be hidden anyways.

STEP 4 – Add Top Structure Supports

Since we added hidden storage using piano hinges, we needed to add additional cross support pieces, so the hidden “doors” have something to sit on. In doing so, we added additional cross supports to both the front and back sides of the window seat for each door.

Also, don’t forget we have the air vent. Because of the air vent, the middle portion of the window seat will be boxed in, and will not have any hidden storage. We did not add any additional supports in that section since it’s not needed.

When attaching the cross supports from the front to the back of the window seat, you’ll need to create pocket holes for each of those as well.

There you have it! All the not-so-fun part of the build is complete. Now, onto the finishing pieces 🙂

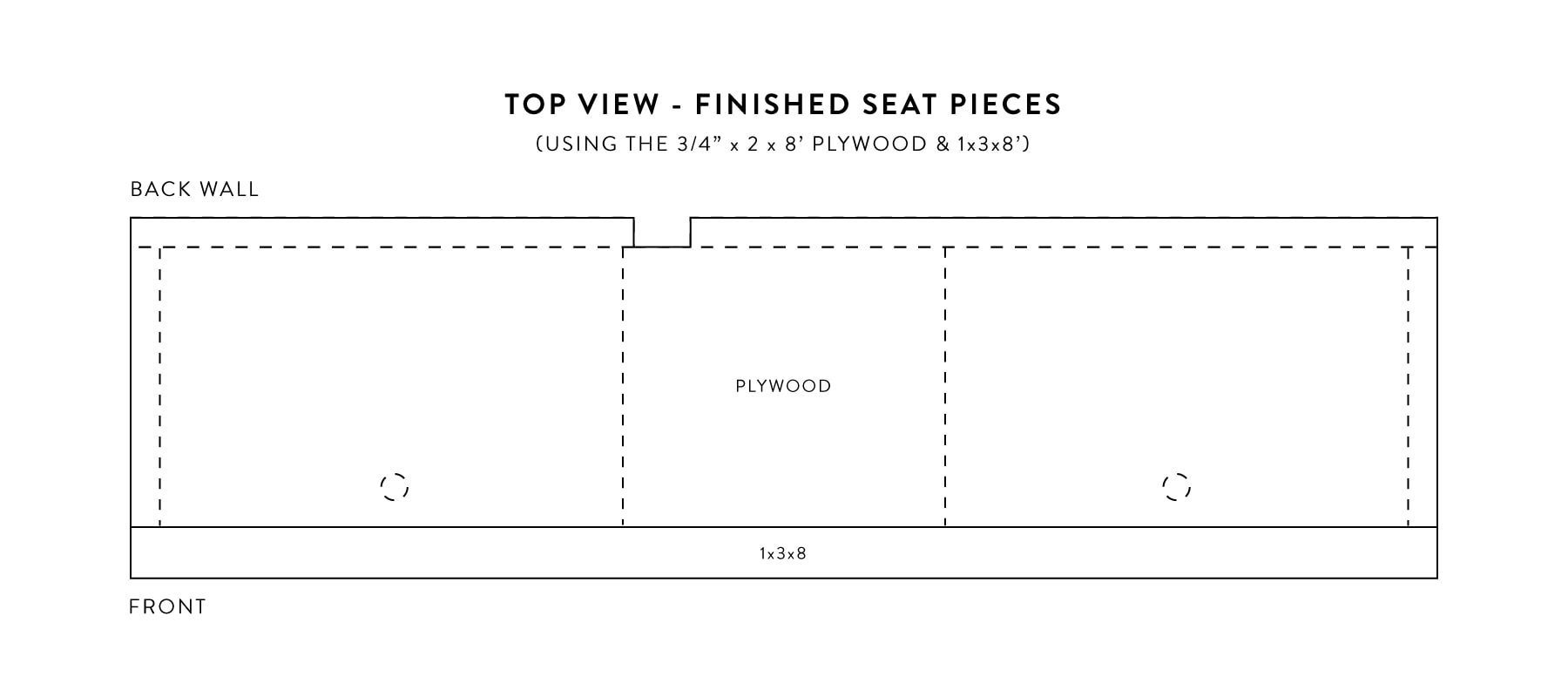

Building The Top Seat & Hidden Storage Doors

This is the tricky part of the whole build. It’s like one giant puzzle piece, that you cut into pieces, and then have to fit the pieces back together ?.

For tools, you’ll need a circular saw, or table saw to rip down the 3/4″ x 2 x 8 piece of plywood to fit the width and depth of the window seat. You’ll need the hole saw to cut out the circle hand hole to lift up your doors. Also, you’ll need your brad nailer to nail down the outside strip pieces. For us, we also had to nail down the centerpiece that is above the boxed in air vent section.

Cutting The Plywood Piece To Fit Window Seat

First, start out by cutting down your overall plywood piece to fit your window seat. We added a front “lip” (is that what you’d call it?) to our seat that sits out a little farther than the window seat area (about 1/4″ past the trim)

Of course, our walls were not even CLOSE to being straight. So, we had to make my cuts on each side of the plywood piece at a small angle in order to fit inside the window seat.

Cutting The Side and Back Strips

Once we cut our main plywood piece cut down to size, we then cut the little strips for both sides of the seat and one long strip for the backside of the seat. These strips are for the hidden storage. Since our walls were not straight, I didn’t want the door to open right next to the wall. Plus, the 2×4 supports are right underneath that, so it’s not like we’re losing that space for storage.

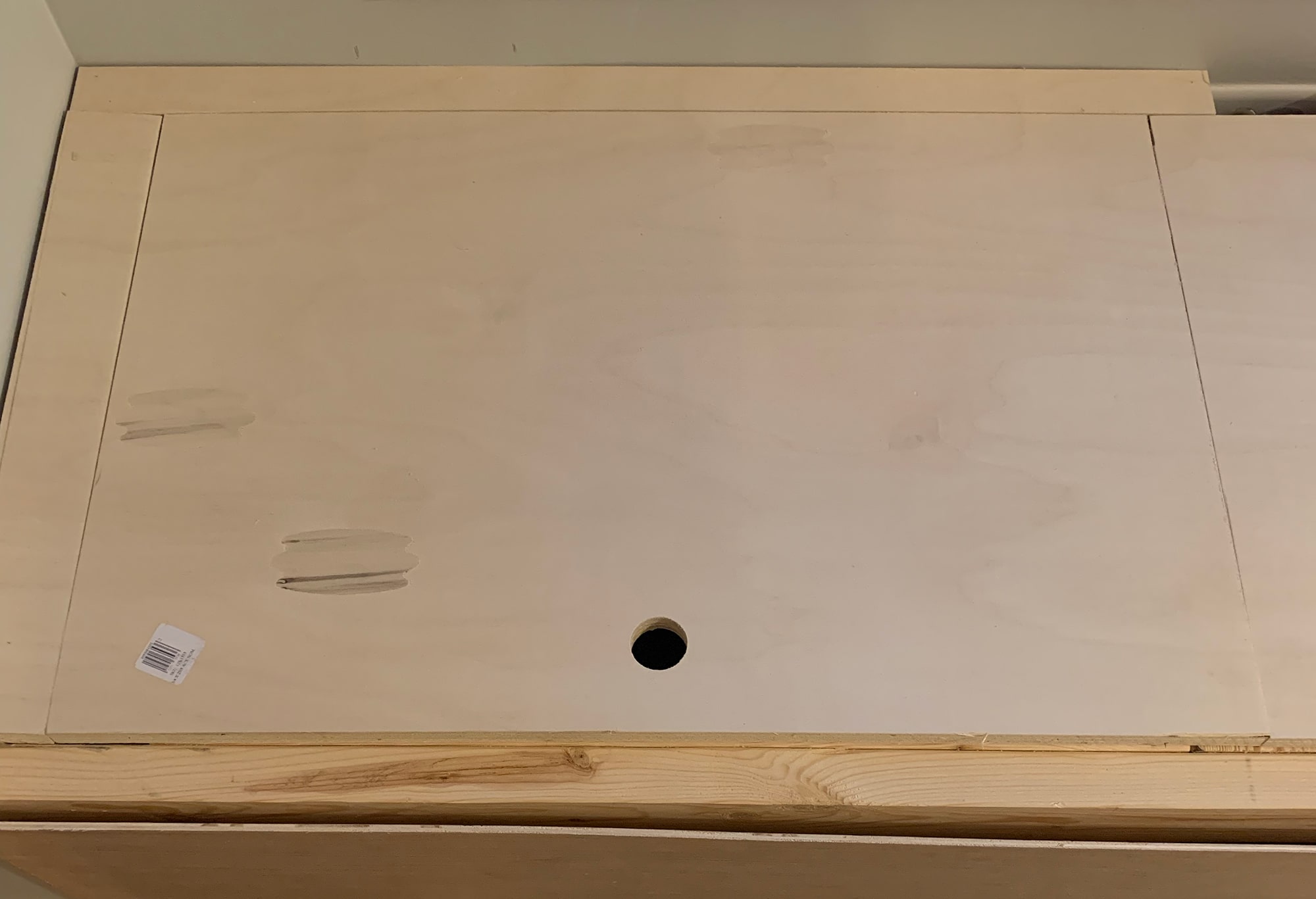

Cutting Out Doors

Once all the outside strips are cut, then you’ll take the rest of your main piece, and cut out the doors and the stationary middle piece (the air vent area for us).

Helpful tip

You may need to sand down the sides of the doors so they have more room to open and close without it being too snug. The blade shaves off 1/8th inch when you rip them down, but a little extra room doesn’t hurt.

Creating Handles For The Doors

In order to lift up the doors, you will need a handle of some sort. Instead of creating a handle that sticks out, we used a hole saw and drilled out a 1 1/2″ circle to use to lift the door.

You could get extra fancy with this, and make it a longer, rectangular handle using your jigsaw. But, we like to do things with efficiently around here… a.k.a. cutting corners if we can ;P

I waited to attach the piano hinges to each door until after we painted everything. I painted the hinges white (with spray paint of course – my favorite thing!) so they would blend in with the rest of the seat.

Nailing Outer And Middle Pieces

After everything fits together nicely, then it’s time to nail down all the outer strip pieces, front lip (1×3) and the stationary middle section. The doors obviously won’t be getting nailed down.

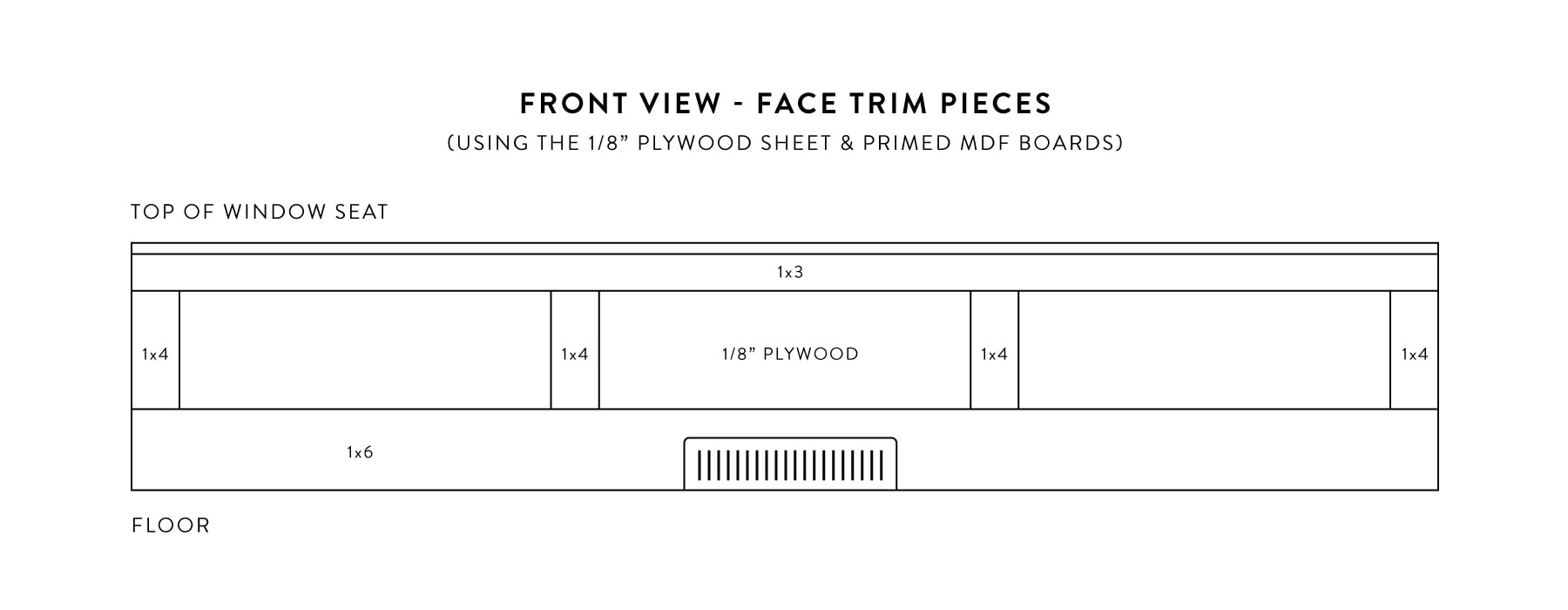

Adding The Final Face Trim

One of my favorite tools is the brad nailer. So this was definitely the most fun part of this project for me! haha. That being said, you’ll be needed the brad nailer. Again, you’ll need your circular saw or table saw to rip down the plywood sheet. You will also need your miter saw to cut all the primed MDF boards.

side note – if you have an air vent as we have, you’ll also need your jigsaw to cut out the hole for that in the plywood sheet.

Cut 1/8″ Plywood Sheet

We had leftover 1/8″ plywood paneling from a previous project, so we used a couple of pieces for the front plywood finishing piece. We just made sure the seem was going to be hidden by a vertical 1×4 trim piece.

If you’re not working with scrap pieces (which you shouldn’t if you bought a fresh sheet of 1/8″ x 4 x 8 plywood!) you’ll just cut 1 piece to fit the entire front of the window seat.

As you can see in the above photo, we had to use our jigsaw to cut out a hole in the plywood for the air vent.

We also took additional scrap pieces of the plywood and boxed in the air vent section inside the window seat.

Cut and Nail All Primed MDF Pieces

After the front plywood panel is up, the face trim pieces can be added. We started by cutting and adding the top (1×3) and bottom (1×6) pieces first.

We used our jigsaw again to cut out a hole in the 1×6 for the air vent.

After we had both top and bottom trim pieces in, we measured the space in between the two pieces to figure out the lengths of the vertical 1x4s. We cut all of these at once, and then nailed them evenly spaced onto the window seat.

That’s it! The building part is complete. All that is left to do is fill nail holes, caulk the trim pieces and then paint!

Painting, Caulking & Filling In Holes

Before painting, make sure to fill in all the nail holes and caulk around the trim to make sure everything is smooth and seamless. After that is all done, it’s time to tape up the area and start painting!

Painting, I think will forever be a love-hate relationship for me. I don’t mind painting… the first coat. But when I have to go back and do the second coat, then it just becomes tedious and I’m over it ?.

Painting this window seat area wasn’t the worst. It didn’t take that long either (thankfully.) As you can see, we also added the trim around the entire window seat area and I’m really happy we decided to do that last minute! It put a nice finishing touch to the entire space. And as you can see above, Figgy couldn’t wait to jump on the window seat.

There you have it! The window seat build is complete! Now, just to add all the final touches. We shared another post that goes into all the details and the full reveal here!

Do you have a spot in your house you could add a window seat? Is that a “wishlist” item for you? Let us know below!

This is absolutely beautiful. I love how you explained each step in detail, including photos. It’s so helpful to those of us new to DIY builds. Thank you!

Thank you so much! We try very hard to be as descriptive as possible because we were both new to DIY and know how some instructions are so vague!

Thank you again,

Tammy & Sarah

This is beautiful and easy to follow. I’m more visual than step by step reading. Although I read it, the images helped me to correct mistakes!! I’m almost done although I have to make some minor adjustments since the window lengths I’m working with go in a stair case fashion in the sunroom but I think it’s turning out quit well for a beginner. Very much appreciate you sharing!!

Hi Tasha!

That is awesome! We love hearing that and are so happy our blog post has been helpful to you during your project! If you’re on Instagram, we’d love to see how your project turns out – be sure to tag us! 😀

– Tammy & Sarah

Can I ask what you used for all then venting? I have a very similar space and I’m going to attempt this, this week!

Hey Megan!

For the venting, we are not experts and are not sure what we did is the best way, but it works! We went to Home Depot and Menards looking at the venting options and found a piece that goes inside the vent and turns and a 90° angle. Then, we added an extender piece to that so it was long enough to meet the new vent box that is now located at the front of the window seat. We used aluminum tape and lined the floors with it and all the seems. We also boxed in the vent itself from the hidden storage, which you can see in the photos!

Hope that helps!

Tammy

Curious about the lights you used. Source? Are they hardwired?

Hi Amy! I have all the details about the lighting in our other post revealing the window seat, which you can find here – https://sammyonstate.com/2019/09/06/window-seat-reveal/

The lights are not hardwired, I used the magic puck light trick! Also, here’s the link to the lights – https://amzn.to/2Fig6Rz

– Tammy

Where did you find the cushion for the top?!

Hi Chad!

I actually made the cushion top! We have more information on how I put it together saved on our Instagram! 🙂

I just checked your Instagram and can’t find the post about the cushion top. Can you link us??

Hi Michael!

It’s under our ‘window seat’ highlight on how I made the cushion top. Here’s the link to the highlight: https://www.instagram.com/stories/highlights/18032025583080000/

Thanks!

Tammy

Thank you so much for the excellent instructional pictures. I couldn’t have built this without them! I had a bunch of car siding left over from another project, so I used that.

That’s awesome!! We’re so happy to hear the instructions came in handy!

– Tammy

I don’t see any detail about mounting the hinges. Can you provide instruction for this step?